A 6-Inch f/8 Newtonian for Christmas

The need to provide a quick Christmas present resulted in the construction of this telescope. The "quick" part was getting the primary mirror from a commercial supplier and building the rest of the telescope from fuel - I mean, "wood". I am not a big fan of the "plywood push-along" telescopes, but sometimes one must compromise to meet deadlines. Construction took the "spare time" from about two weeks; it began well into December and was completed in time for Christmas morning.

The tube assembly is carried in a saddle to which the altitude bearings are attached. By unlatching four draw-catches the saddle separates into two pieces. This allows quick balance adjustment or instant removal of the tube for use on other mounts.

On the operator's side of the mount can be found a handy eyepiece rack and altitude and azimuth circles. The numerals are of the stick-on vinyl type over which a few layers of clear enamel is applied. The thought was to use the circles in conjunction with a planetarium program on a laptop computer for finding daytime objects.

A spirit level is screwed to the bottom plate of the "rocker box" and one foot of the base is labled as the "East foot". The high gloss of the clear overcoat on the base plate azimuth circle is obvious in the photo above where the reflection of one of the white teflon azimuth bearing blocks can be seen (directly above the "East Foot").

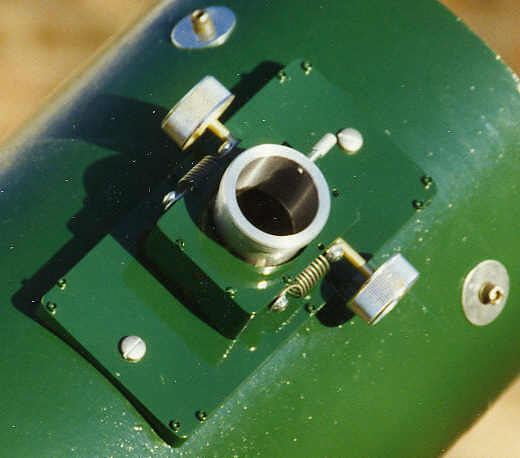

The focuser is of the spring-loaded Crayford type but extra effort was expended in cleaning up its lines to keep dust and moisture out. For more information on these easy to make and very effective focusers, CLICK HERE.

The photograph below uses the morning sunshine to illuminate some of the details of the tube baffling/strengthening technique I use for "Sonotube" type telescopes. A skeleton is constructed from plywood rings which are held together with long pieces of hardwood dowel inserted through holes in the rings.

The inner edges of the rings are beveled to minimize the chance of incident light reflection, and the rings are spaced along the length of the tube to reinforce the high stress portions of the tube; such as the front end, each side of the spider and focuser attach points, areas near the saddle, and where the primary mirror cell is installed.

After the skeleton's glue is dried, it is pressed into the tube and glued in place with a waterproof aliphatic resin type wood glue (Titebond II is excellent stuff). The tube is then cut and drilled in the appropriate places for the focuser and such, the hole's edges sealed with glue, and when all is dry the paint is applied.

This little telescope has been a joy to use. The mass-production primary mirror turned out to be of surprisingly good figure delivering very sharp images, and the scope instantly separates into two easy-to-carry pieces by simply lifting the tube/cradle off of the mount. Toss them in the back of the car with a few eyepieces and motor on down the road. Nice.

I may make another push-along Newtonian some day.

- Jim Sapp