Curiosity got the best of me once again when, browsing through a surplus catalog, I happened across an ad for a Gregory-Maksutov Cassegrain spotting scope for under $70 - complete with tabletop tripod and soft case. I've spent more than that on a single eyepiece before, and since I've been in the market for a lightweight, inexpensive (disposable if need be) spotting scope with a 45 degree eyepiece for the backpack, I took the bait and mailed off my money.

The item arrived in a plain corrugated box of the light yellow Asian type, which then contained a brightly colored glitzy box with attractive photos enticing dollars to leap from the wallets of prospective buyers. Within this box I found a fairly nice black vinyl case with velcro closure and shoulder strap. The interior also has a removeable velcro-attached partition to keep two items (scope and tripod) from damaging each other. The top flap folds well over the top of the case but there are no flaps on the tops of the sides to keep dust and rain from entering the case. I suppose the case would work very well for carrying two bottles of wine.

The included tabletop tripod is a valiant attempt. It is variable height with fairly crude slow-motions on both axes. It works, but being extremely light and nearly 100% plastic, I found it to be only marginally useable with this telescope. With a bit heavier spotting scope (Bushnell Sentry) it is unsatisfactory. there is just way too much flex in the head and vertical post. As you tap or push on the end of the scope you can see the bottom of the vertical post weave back and forth between the legs.

The image below shows the typical screw-and-spring tangent arm slow motion configuration. Cheap and effective.

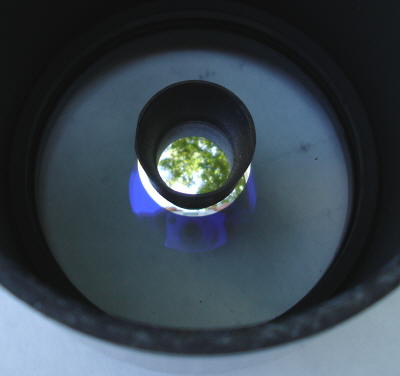

The telescope itself is extremely light, weighing about 1 pound. Upon removal of the dustcap the pretty blue coatings and the shiny reflections in the primary mirror got my hopes up that perhaps I had come across a diamond in the rough.

I figured if the permanently attached zoom eyepiece had any kind of decent quality, the scope would fill my need for a backpack scope; but upon mounting it to the tripod and focusing on a rooftop and some tree leaves in the late afternoon sun, I was reminded that you get what you pay for in the world of consumer optics. It all went downhill from there.

The zoom eyepiece contains coated optics, but the apparent field of view is quite small - perhaps 2/3 that of the equivalent (metal) version Bushnell includes with their 18-36x50mm offering. The plastic tripod would be satisfactory with this telescope if the focusing knob were smoother; but it is sticky (or "jerky") requiring fingers from two hands to provide opposing forces on the knob to get to critical focus (not that there really is a "critical" focus with this eyepiece). By the feel of it, it is obvious that the focus control is a plastic threaded rod riding in a plastic nut. I would suspect that winter temperatures would make the focuser even less useable. The grease added to the plastic parts does not mask the design flaw.

At this point, it was my opinion that reworking the focusing mechanism in metal and deleting the cheapie zoom eyepiece for a fixed power of say, 40x would make a tremendous improvement in the useability of this product. Someday, these optics marketing guys will learn that "zoom" is NOT a good thing from the end-user perspecetive in the lower levels of the price scale. It may be a selling point to the ill-informed, but a fixed power eyepiece of higher quality could be provided with no increase in cost, making a better overall product for the end user.

A new day brought the desire for more tests on my new acquisition. Unfortunately, the first test perfomed was an unintentional drop test - from about 4 feet onto a hard concrete floor. The unit did not survive this test, so further optical tests were not to be. The primary mirror was now loose and would flop back and forth making focusing impossible. An item destined for backpack service should be able to survive such an accident; but this scope - even with such negligible mass - could not.

The bright side of this test failure was that it provided motivation and opportunity to disassemble the unit to find the cause of the failure, the secrets of the manufacturer's assembly process, and a repair affected. Close examination of the unit revealed no access to the interior other than the front meniscus lens mount; but the retaining ring is simply a plastic ring glued in place. It became painfully obvious that the most direct route inside was via band saw.

It was a very simple procedure to rotate the soft plastic side of the unit against the moving blade of a band saw. One cut allowed access to the front end of the primary light baffle (which is the secret to removal of the remainder of the components). Unfortunately, that was the second cut. The first cut was around the perphery at the end of the tube nearest the eyepiece, which did not allow the two parts to separate - but at least it allows better photos of the interior.

Here is an exploded view of the C65 as this point:

Moving from left to right, we have our cheapie zoom eyepiece as it is glued into the bottom of the tube assembly. Molded here are the two standoffs to which the backplate is screwed.

The backplate and the primary baffle tube that is mounted to it are virtually the only metal parts in this thing. The 45 degree erecting prism is held in a cage on the back side of this plate. It is poorly secured to the plate via two plastic studs that extend through holes in the plate and are melted or otherwise flattened to serve as rivets as seen below.

This one-axis mounting scheme allows the prism to rock up and down. A dab of epoxy between the top of the prism cage and the backplate upon re-assembly corrected this design flaw.

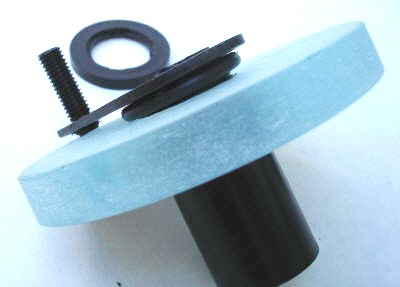

In the next view we see the heart and soul of the telescope. At left is the prism in its cage, affixed to the backplate with the primary baffle tube extending to the right. The primary mirror is carried by a plastic sleeve that slides forward and back on the baffle tube. The cone-shaped part threads into the front end of the baffle tube and limits the forward travel of the primary mirror sleeve.

At the immediate back of the mirror is a rubber O-ring to provide some cushion for thermal expansion & c. Immediately behind the O-ring is the focus screw bracket. (This is the other metal part of the product.) The bracket extends radially away from the center and carries the plastic threaded rod which the focus knob uses to force the mirror assembly forward and back. And finally, a plastic threaded ring screws onto the sleeve to hold the bracket, O-ring, and primary mirror together. This is the point of failure of the drop test.

The thin plastic of the sleeve broke. It could not retain the inertia of the primary mirror applied through the O-ring and bracket and separated upon impact. This is yet another design flaw. The sleeve should be made of a metal with similar thermal properties as the baffle tube. Once again, the great globs of green grease between the baffle tube and the mirror carrier sleeve do not mask the design shortcoming. (Yes, I know - its only $70...)

The focuser knob itself is contained inside a well in the side of the tube. I actually like this design feature as it effectively seals the interior of the tube against dust and moisture.

Finally, and as is true of most Gregory-Maksutov telescopes, the secondary baffle is simply glued to the meniscus with the secondary mirror being an aluminized spot on the lens.

Upon repair and reinforcement of the primary carrier sleeve with a liberal dose of Devcon 5-minute epoxy and subsequent re-assembly, the three tube sections were re-glued with plastic welder and the telescope returned to the tripod for further tests. The slight shortening of the tube due to the width of the bandsaw blade kerf was sufficient to extend minimum near focus about 10 feet. Oops. (This was a small price to pay for learning the secrets of the scope though!) Collimation did not turn out exactly perfect either.

After this experience with the $70 option, which proved to be no option at all, the solution to my cheap backpack scope will remain the Bushnell $90 offering, which is a rugged, waterproof, rubber armored 50mm refractor-type scope with a semi-decent metal zoom eyepiece providing 18-36X. The simple diecast metal tripod Bushnell provided is superior to the plastic one provided by Celestron. There are no slow motions, but there is stability. More detail can be seen at this Bushnell's 30x (with chromatic aberations) than can be seen with this Celestron's 90x. The search continues...

I am still of the opinion that the optical components of the little Celestron (less the crummy zoom eyepiece) have real potential if mounted in a well-executed metal tube assembly with well made metal parts and used in conjunction with real eyepieces. This optics set is not destined to remain long in its present temporary plastic prison. I suspect there is a bright future for it waiting patiently in my workshop.

- Jim Sapp

Summer, 2009