This beast's claim to fame is that it is the only example I know of an amateur-made telescope mount using an anti-backlash spur gear as the main R.A. drive gear. It is an ugly but accurate mount with setting circles that will put an object within the field of a 100X eyepiece.

I built this telescope and mount about 20 years ago and it is another example of "design-as-you-go" based on available materials rather than forethought, which is fairly common (by necessity) in the ATM world. It gave service in my backyard for about 4 Mars oppositions (8 years) providing rock-solid high power views. I kept it covered with a canvas tarp when not in use and cleaned the optics with the garden hose when necessary.

The tripod-shaped pier is made of welded steel pipe and equipped with large steel wheels like you see under semi tractor trailers. The center part of the pier is equipped with a large eye bolt that served as an attachment point for a heavy turnbuckle that clamped the pier to a large steel "corkscrew" held 3 feet into the ground by a couple of bags of concrete and a few short lengths of rebar. The force of the wheels on the ground was distributed a bit with three pieces of flagstone.

The telescope and mount are all machined metal construction that weigh about as much as a large motorcycle, with a rugged but inefficient design requiring complete disassembly for transport. This mount is NOT mobile. (It now languishes in my garage and is slowly yielding parts to other projects since I now live in a light polluted area with many trees obscuring the sky, which forces me to be mobile for astronomy.)

The 8-sided open-frame tube presents only a very slight profile to the wind and allows very rapid cooling of the optics and a total absence of thermal tube currents. This worked out well in this semi-arid environment but would not be suitable in a humid area due to dewing issues. It is made of sections of ½ inch steel hex stock which are each drilled and threaded to serve as "long bolts" that screw together to form the framework. The tube's large round rings were cut from ½ inch aluminum plate on a milling machine with rotary table. Two of the "bolt" sections near the sky end are made of threaded rod which each carry threaded brass counterweights for balancing accessories at the eye end.

Both axles are 3 inch solid steel shafts mounted in 5 ½ inch inner diameter ball bearings at the top ends, tapering to about 2 inch ball bearings at the lower ends. The two main counterweights are 7 inch diameter x 2 ½ inch thick stainless steel, knurled on the perimeter and threaded to serve as nuts for clamping any additional weights between them on the threaded counterweight shaft.

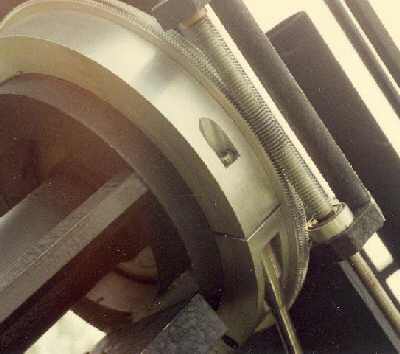

The main drive gear is a 9.5 inch diameter 144-tooth anti-backlash spur gear, driven by two pinion gears which are each driven by 120 tooth worm gears. Each of these is driven through a set of angle gears by separate synchronous AC motors mounted on a plate near the south R.A. bearing. My thinking was that load and tooth error would be divided between the two motors, which seemed to have worked since the only noticeable periodic drive error takes 10 minutes per cycle.

The six brass knobs make up the R.A. drive's friction clutch adjustment. They are threaded into the hub of the AB gear and adjust the drag of the drive against the polar shaft. The ends of the drag adjustment screws put pressure against a steel shim that is recessed into the inner diameter of the AB gear's hub. This isn't the most elegant design, very crude in fact, but it surprisingly works very well on this heavyweight. A standard pressure-plate clutch system is much simpler to implement and a much smoother design.

The declination slow motion consists of an 11inch diameter 440 tooth worm wheel mounted to a thick ring that serves as a clamp to lock the gear to the upper declination bearing housing. The worm assembly is fixed to the saddle plate that the telescope is mounted to.

Wind or vibration was never an issue with this telescope. I have used it in 80 MPH gusts (as measured by an anemometer mounted at the top of a pole nearby) wearing a motorcycle helmet for protection from flying debris while hanging on to the telescope for support. The image was steady even when I was not.

- Jim Sapp